September 13, 2025 – ABI, a leading supplier of bakery solutions, including bagel production equipment, robotics, and automation solutions, will unveil its new Robotic Scoring System, KATANA II, at IBIE (West Hall, Booth 2333) in Las Vegas from September 14 to 17. Featuring a new software with a user intuitive interface and improved accessibility, KATANA II offers high scoring precision for any type of dough.

As product ranges expand, production lines face increasing operational complexity while access to skilled labor continues to tighten. Today’s industrial bakers must adapt quickly to shifting market demands, deliver a wider variety of products, and maintain high levels of performance while navigating ongoing labor shortages. For over 35 years, ABI has been delivering innovative solutions that help the baking industry rise to these challenges.

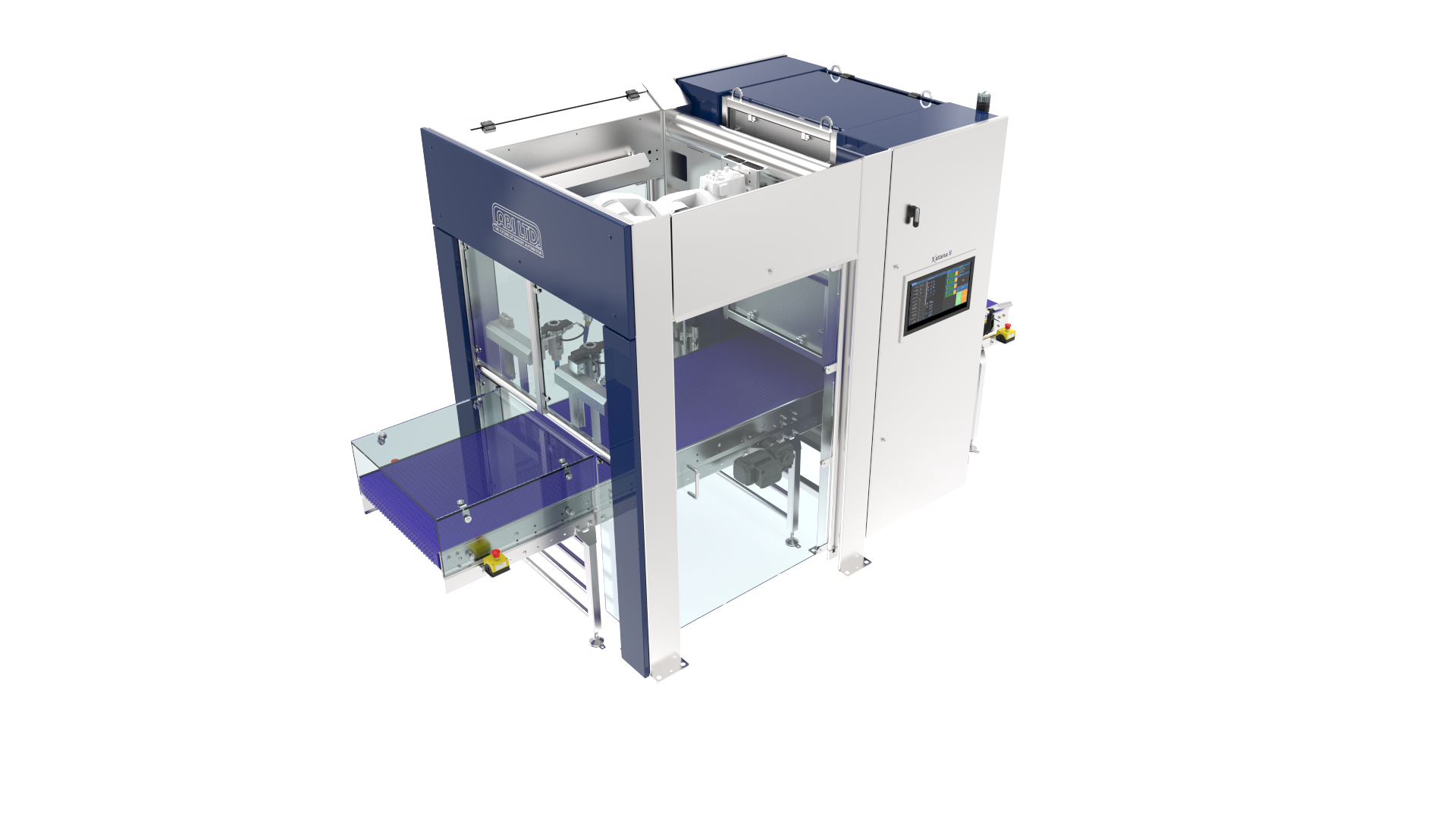

The KATANA II Robotic Scoring System is the latest scoring technology developed by ABI. At its core is a brand-new, proprietary software with an intuitive in-house interface, designed to make operation easy for operators. Combined with three End-of-Arm Tools and a 3D vision system, KATANA II ensures precise scoring across a wide variety of dough types, from classic to complex patterns. Its sleek, compact design reduces footprint and streamlines cleaning and maintenance operations.

KATANA II: a Proprietary Software designed to make operations easy for bakers

KATANA II combines precision and simplicity in one solution. Its intuitive, proprietary software and ergonomic interface allow a single operator to manage scoring with standard training—no technical or programming expertise needed. A virtual assistant, along with step-by-step instructional videos on the HMI, guides users through recipe setup and scoring parameters, with clear visuals at every step.

“We designed KATANA II so bakers can focus on baking, not programming,” explains Mauricio Duque, ABI Software Designer. “The virtual assistant guides users through setup, provides real-time previews of scoring patterns, and lets even first-time operators achieve precise results with confidence.”

Precision Scoring Across All Doughs

KATANA II delivers precise scoring on any type of dough, from classic to complex pattern. Advanced features like Dynamic Depth Control (DDC) and Dynamic Shape Control (DSC) use the 3D vision system to automatically adjust to the product’s contours and size, ensuring consistent cutting depth and aesthetic uniformity.

“These custom-built features we developed in our KATANA II software allow to scale the scoring pattern in real time, adapting to each individual product as it comes through”. Shawn JAMALZADEH, R&D Manager.

One robot, three tools, high performance and flexibility

But adaptability does not stop there. To help industrial bakers meet market expectations for product diversity, the KATANA II Robotic Scoring Solution integrates three End of Arm Tools. Each tool is optimized for specific dough types: the waterjet handles straight doughs and complex designs at high speeds, the ultrasonic drag blade adapts to stiffer doughs or those with inclusions, and the plunge blade is perfect for thick or coated products such as pretzels or specialty breads. Fully automated changeovers take under 60 seconds, allowing seamless transitions and uninterrupted production while maintaining consistent product quality.

The KATANA II all-in-one cell compact design offers a small footprint to integrate into any facility.

KATANA II is also “connected-ready” and compatible with the MyMecatherm digital platform, giving operators real-time insights into performance, production rates, and quality metrics to support proactive decision-making.

New Design for easy cleaning and maintenance

Last but not least, The KATANA II offers full accessibility, simplifying cleaning and maintenance. Transparent doors provide clear visibility and easy access to the robot, while the vision cell is neatly housed in a panel above the conveyor belt for straightforward cleaning.