For the first time, ABI has been awarded an “Committed Company” medal following its assessment by EcoVadis*, an international organization that evaluates companies on their performance, commitments, and practices in terms of sustainability.

The company also stands out in its sector, ranking:

• Among the top 27% of companies assessed by EcoVadis in terms of overall score.

• Among the top 21% of companies assessed in terms of Social & Human Rights.

• The top 23% of companies assessed in terms of Sustainable Procurement.

The criteria audited covered ABI's entire CSR approach, based on four fundamental pillars: the environment, social & human rights, ethics, and sustainable procurement.

Sustainability as a Guiding Principle

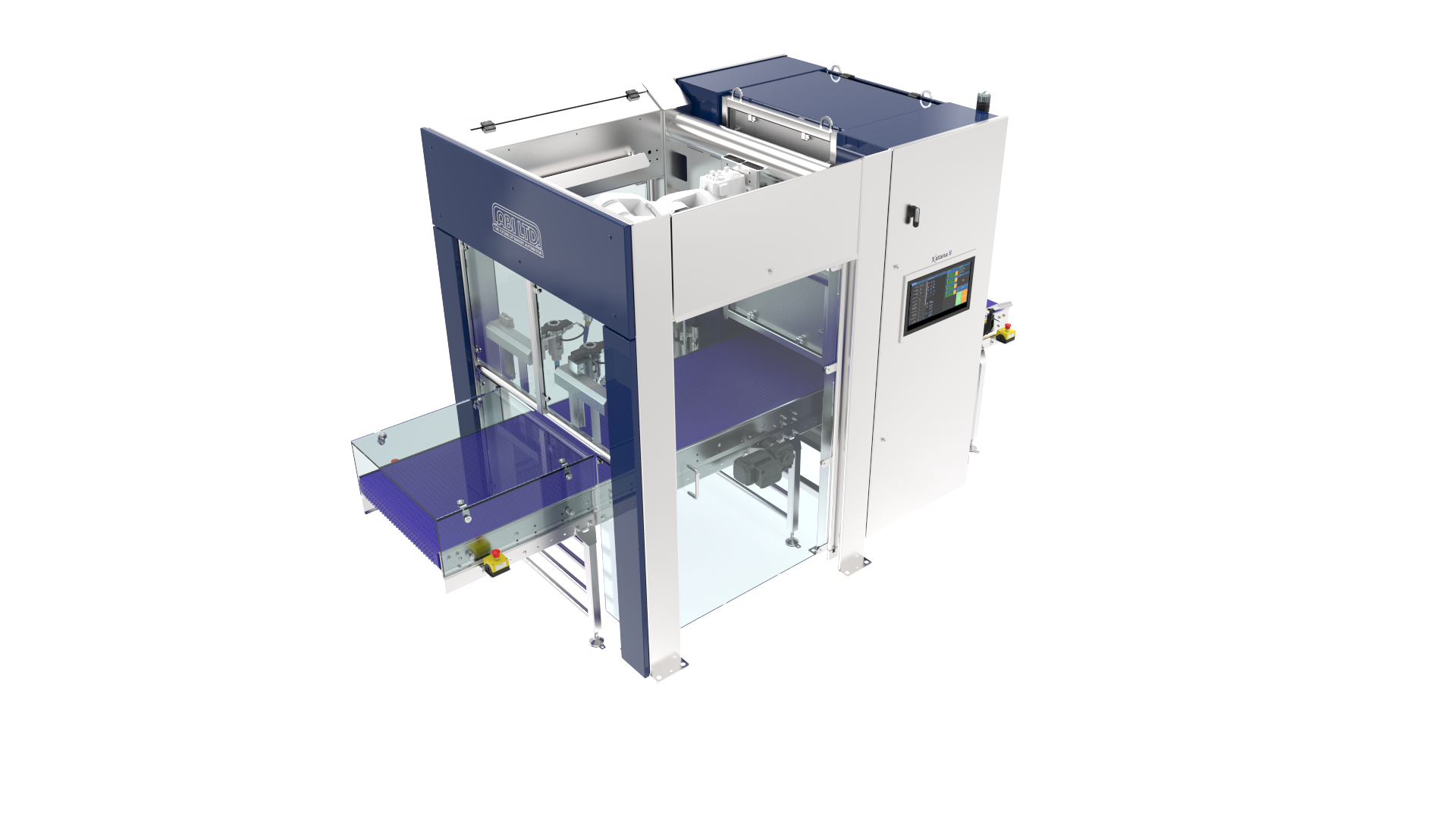

ABI's commitment to sustainable development is concrete: the company is working to make industrial production more responsible through three major areas of commitment:

• Area 1: Setting an example in energy transition and the circular economy

• Area 2: Supporting everyone’s development in a safe environment

• Area 3: Supporting our customers in their sustainability ambitions

To structure and prioritize its actions, ABI has implemented a strategy to ensure the effectiveness and consistency of its sustainability strategy.

“We are proud to receive this medal, which recognizes the structure of our sustainability approach and our commitment to intensifying our efforts. At ABI, we continuously work to develop our equipment and meet market expectations, while fully integrating social and environmental considerations into our development approach.”, says Alyson Slapkauskas.

READ OUR SUSTAINABILITY CHARTER

*EcoVadis certification is adapted to the size of the company being assessed and its sector of activity. The analysis and final score are weighed accordingly in a scorecard that presents the company's strengths and possible areas for improvement. The final overall ESG score ranges from 0 to 100 and is the result of the weighted average of the four themes included in the assessment: environment, ethics, social and human rights, and responsible purchasing.

About EcoVadis

EcoVadis evaluates companies' sustainability performance based on a strict validation methodology.

Their methodology is based on international sustainability standards, including the Global Reporting Initiative, the United Nations Global Compact, and ISO 26000, covering more than 175 countries. The sustainability scorecard illustrates a company's performance through 21 indicators divided into four themes: environment, social and human rights, ethics, and responsible purchasing. More information on EcoVadis.